Here its is after the 1st or 2nd ride:

Here it is about 9 months later - still no changes

Here it is when I added a 4iiii left hand crank power meter

Here I an riding it at Mallory Park race circuit - still no major changes

In 2018 I bough the "official" Giant rubber bungs to plug the holes in the frame for the Giant Cadence sensor - these bungs fit in the non-drive side chainstay. I got these from www.giantbikespares.com. The postage cost as much as the parts. I got this because I was now sometimes riding the bike when it was damp and did not want to get water in the frame

This year (so about 3.5 years after I bought the bike) I finally gave up and downsized the chain rings from 52-36 to a more normal Compact (50-34). I bought Ultegra rings even though the cheaper 105 rings are completely compatible to keep the specification correct

The main difference between the Ultegra rings (above) and the 105 (not shown) is that the Ultegra big ring is a metal/nylon composite whilst the 105 is all metal (with integral strengthening "ribs"). You can see the nylon quite clearly above. I also needed to change the chain at the same time as it had done over 4000 miles, although the chain wear checker did not suggest that it was over the recommended 0.75%. Obviously changing the front rings (a 2 tooth reduction on both rings) meant I needed to also look at the chain length and the position of the front dérailleur. I took some photos before for all the gear extremes (52-28, 52-11, 36-28 and 36-11) to look at the original chain relationship and to compare to what it was going to be like with the new extremes (50-28, 50-11, 34-28 and 34-11).

|

| 52-11 |

|

| 52-28 |

|

| 36-28 |

|

| 36-11 |

|

| 50-11 |

|

| 50-28 |

|

| 34-28 |

|

| 34-28 |

I also noticed that although the original chain was not over 0.75% wear, the new chain actually ran more quietly and smoothly and shifted better, so clearly the wear indicator method does not always show a true real world level of wear.

Some careful photos also meant that I could reset the front dérailleur into the new lower position:

There was one real benefit here with Di2 - this was that I didn't need to do anything to reset the cable length like I wild have had to with a traditional mechanical set up

This photo is with the original 52 ring so I set the same height gap for the 50 tooth ring

The change to the smaller front chain rings is by far the biggest change to the bike - and the outcome is that it is easier for me to ride and I can use more of the cassette, so it was money well spent. For info I got the rings from Rose Bikes (ignore the .uk domain - they are a German company). Its clear that although the 6800 series Ultegra is only one generation old it's already seen as obsolete as I could not get these rings in the UK

I have also needed to swap the rear tyre out - it was still just about OK at 4600 miles but the wear indicator was long since gone and the tread area no longer round:

The tyres are Giant P-SL1 700 x 23c. These are around £30 each and are starting to be replaced by P-SL2. However by compete chance I looked on EBay and saw a pair of almost new P-SL1 tyres. I bid and got the pair for only £22. They really had done only a few 100 miles at most - what a bargain

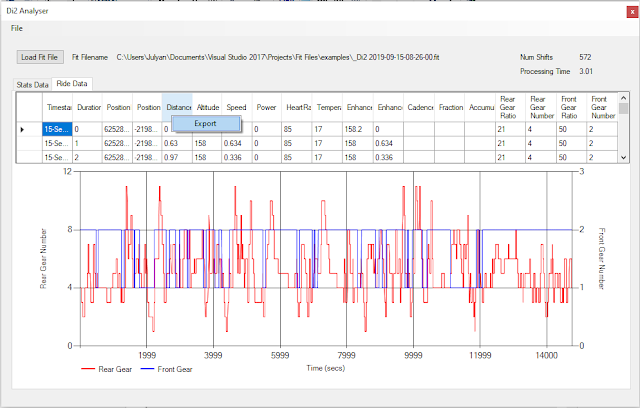

The final changes I have done are to fit a Shimano SM-EWW01 unit so I could read the gear position and other Di2 data into my Garmin. This is documented here: di2-monitoring

So - my bike is still almost as built but has some small changes, some more visible than others. It's a great bike but as I will freely admit - a better bike that I am rider